This is probably one of the most important updates I’m going to do about MTNU (excluding the final release announcement of course). There’s a lot to cover so buckle up and let’s get started!

Last week I’ve finally met with the GMK guys in Germany to review the first injected MTNU prototypes and to decide on the next steps. I was expecting “corporate courtesy” and instead I got sincere kindness and a lot of fun.

First of all let me thank Christoph, Franz and Franziska for their hospitality and professionalism. Christoph is one of those guys who restores your faith in humanity, he’s an incredibly nice person and despite being very busy he always finds the time for you. Franz and Franziska are the engineers assigned to MTNU and the passion they put in their job is contagious. They gave me the company tour and it was energizing seeing their enthusiasm describing all aspects of manufacturing even though –I’m sure– they’ve done that dozens of times already.

I know there has been some criticism these past few months addressed at GMK, mostly because of the long production times. It’s easy to spit out judgment on the internet especially when the addressee is some big company; but if you spent 5 minutes with these guys you’d understand how undeserved the hate is.

Manufacturing time and delays

Let’s get that out of the way. GMK went through an expansion process during possibly the worst time ever (a pandemic) but almost all sectors of the company are transferred now and production is finally catching up. By the time MTNU will be released production should be at full capacity.

Before you ask: No, MTNU won’t interfere with the standard Cherry profile as the two run on different sets of machines.

Manufacturing process

I know how keycaps manufacturing works and I’ve seen quite a few molds and injection machines but I’ll admit I’m impressed by GMK process. The main difference is in how the molds are designed.

Often to cut on costs you have a relatively big mold with as many keycaps as possible on it, that is a good way to lower the number of injections needed to cover all the kits. What you gain in production speed you lose in flexibility and wasted material.

Allow me a quick example. Say the “Esc” key is in the same mold as the modifiers, but in your design Esc is of a different color than the modifiers. What they do is to inject the whole mold with the modifiers color first and throw away the Esc key, then inject the mold with the Esc color and throw away all the modifiers. This way you wasted 99% of plastic from the second injection.

But it’s not only a matter of wasted resin (don’t worry it can be reused… generally), with one-big-mold it is complicated to change kits or add new keys and that becomes frustrating after a couple of years when new layouts come out.

GMK instead uses a smarter system that reduces waste and enhances flexibility. Can’t go into details here but I could definitely see the difference with certain Chinese manufacturers.

Material

Before delving into the actual prototypes I need to talk about materials because a lot has changed since the last update.

We thought a PBT blends could have been the ideal compromise but ultimately MTNU will be full blast double-shot PBT.

Designers will have to familiarize with the new material as it interacts a little differently with pigments but as far as I can see highly saturated hues are not an issue (if that is your concern).

Full PBT also means that at release MTNU will be PBT-only but it might be possible to add an ABS option in the future if the profile goes as well as we all hope.

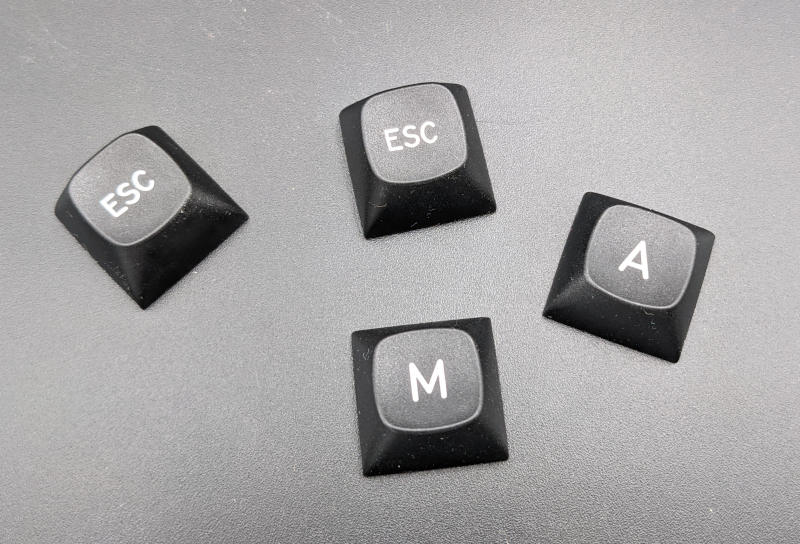

The first prototypes

Please note that the pictures refer to very early prototypes. It’s just to let you know that we are working on it and we are on track for a 2023 release but they are by no means final!

That being said we nailed a few things already. The surface texture together with the PBT material is simply superb. Especially the dark colors have a nice velvety finish that gives the profile a very “pro” look.

The texture is quite unique, definitely on the smooth side but with a very light grit that will help hide the injection flow marks. Personally I love it and it’s one great defining characteristic of the profile.

Next would be rows angle analysis. This is a tough one as it’s impossible to get it right for every scenario.

First of all we are limited to the R1-1-2-3-4-4 rows distribution. It means that R1 and R4 have to work on two rows so the angle has to be averaged and can’t be too steep. Especially R4 risks to become too sharp on your thumbs if it’s too angled.

We are still experimenting but overall typing is very pleasing, the fingers float on the keys without hitting anything that they shouldn’t and I’m overall very happy with the profile curve.

A quick note about the sprue mark. I’ve been asked where it is located and if it could be placed on the bottom of the key where it wouldn’t be visible at all. Because of the completely automated manufacturing process the mark has to be on the back of the key and cannot be placed on the bottom. It’s a very small dot that is barely visible but you can feel it with your finger. This can’t really be helped but considering you will never see it, I hardly believe it’s a deal breaker.

A modern profile with a vintage twist

Spherical top keycaps are synonym of vintage keyboards but MTNU is actually pretty sleek.

The top surface is not centered like in MT3 but shifted to the back similarly to the Cherry profile. This characteristic gives the profile a more modern look, not to mention it helps with front-side printed legends in case you need them.

The font also is inspired by old keyboards and typewriters but it has been revised for a more fresh look. I find that the end result is very cozy but stylish even though there’s still work to do to make the thicknesses consistent on all legends.

Packaging

I’ve read some criticism for GMK packaging on social media recently. There might be a margin for improvement but I’m 100% with GMK here.

I understand that many in the community are keycaps collectors and not just avid typists so adequate storage is important, but –sorry to be blunt– we are talking about a moderately futile item that do not requires any special storage precaution (just don’t put them under the sun).

I feel bad already because we are manufacturing plastic items but at least the keycaps themselves serve a purpose. Every single keycap manufacturer I know doesn’t give a damn about the environmental impact of their packaging. PBTFan goes as far as using more plastic for their super sleek boxes than the keycaps themselves. Drop uses these transparent plastic trays; I have the house full of those things by now and I don’t know what to do with them anymore.

Keycaps packaging is either trashed the second you open the box or stored on a shelf for ages while you wait for that perfect keyboard group buy you joined 2 years ago. I’m pretty sure we can all live with a less cool box if that means doing the right thing.

GMK trays are completely biodegradable and I admire a company that invests in environmental friendly solutions.

I’ve also seen the new trays that are much sturdier so GMK is actively improving the product when a problem arises.

Next step

We are optimizing the manufacturing process, there are still a few things that need to be sorted out. We are also trying different angles for the rows to see how that affects the typing experience. Meanwhile I’ll keep working on the legends thickness and alignment.

The first set to be manufactured will be likely a slightly updated Susuwatari and then a few classics like WoB, BoW, Beige, Dolch… But that’s just the beginning, we hope designers and vendors will jump in and more option will be available later in 2023.

As for timing I believe the pre-orders will start just after the winter. Unfortunately I don’t have pricing yet but it should be comparable to the Cherry profile. Yeah, I know, not the cheapest but I hope this post will shed some light on the whole production process, the people who work on it and why this is a premium product.

Exciting times! I’ve seen MTNU 3D printed models already but having an injected keycap in your hand is a completely different experience. Things are getting real and honestly these keycaps are way better than I anticipated and they are not even close to the final result :)

Stay tuned and join my Discord server for day-to-day updates!

Comments

Very exciting. Thanks for posting. Looking forward to getting these on a board one day soon!

“Before you ask: No, MTNU won’t interfere with the standard Cherry profile as the two run on different sets of machines.”

This feels misleading. Sure it won’t further delay cherry sets but the money, time, space, and manpower used to set up and run additional cherry machines

*Could have been used

as of now production is 100% on Cherry profile. MTNU is on engineering now. Later when the machine is configured it goes on its own. Configuring one machine is not what slows down production.

Really excited to see that this project is finally coming to fruition! I know I’ll definitely be buying a lot of sets haha

I pray there will be “International” kits for all the new sets because I am really in love with the profile but I rarely ever do ANSI builds these days.

Thank you matt3o for your efforts and the love you put into your projects!

I second this but i know from GMK andy’s comments on Reddit, international kits and language support depends on the designer. they also said having the packaging being fully automated coming in the future will make things a little easier for more language support. but i’m happy to see international kits becoming more and more standard.

Very cool! Looking forward to trying them! Are there going to be novelties on MTNU sets as well or in the beginning all sets will just be different color variations?

yeah I bet there will be novelties :)

Full PBT? hell yeah!

Great news about doubleshot PBT, and that side curve is so sexy!

Can’t wait!

That it will be full PBT is great news. I’m in as soon as there’s a good ergo kit to go with the sets. A blank ergo kit would be perfectly fine tbh, seeing as it’s impossible to cover all layouts.

If we get the minivan keys, I buy

It looks amazing, I can’t wait to try it! I really hope that you and GMK consider introducing the international south kit as more or less a standard; I’m italian and I’m a researcher at a university, hence the Iso-it keys are quite useful for my needs.

As always, great work!

Very excited as always to see an update. I’m going to be very interested as to how these work on a Dactyl. I’ve had to switch to the curved key-well because of hand pain issues and the MT3 sets I have end up being great. I know I’m a drop in the bucket when it comes to the market share, but I’m hoping MTNU will be as friendly in this regard as MT3 has been. It sure looks like it will be a better fit that just using SA based on the photo.

Looking forward for these! I hope you’re planning on doing a dvorak kit, this is a must! and do you plan to do a 9009 color scheme as well? I love the MT3 one but I’m much more inclined on supporting this new project.

Have there been any decisions on what range of keycaps will be made available with MTNU? Full 104, TKL, 60%, etc? Relatedly, will there be volume-control and similar “extras” keycaps available?

Forgive me if these questions have already been answered, but I didn’t see a mention of them in this post.

Kitting will be announced in a matter of days! Stay tuned!

Sorry, comments are closed but you can still get in touch with the contact form.